General info

Sootblow more, with less steam

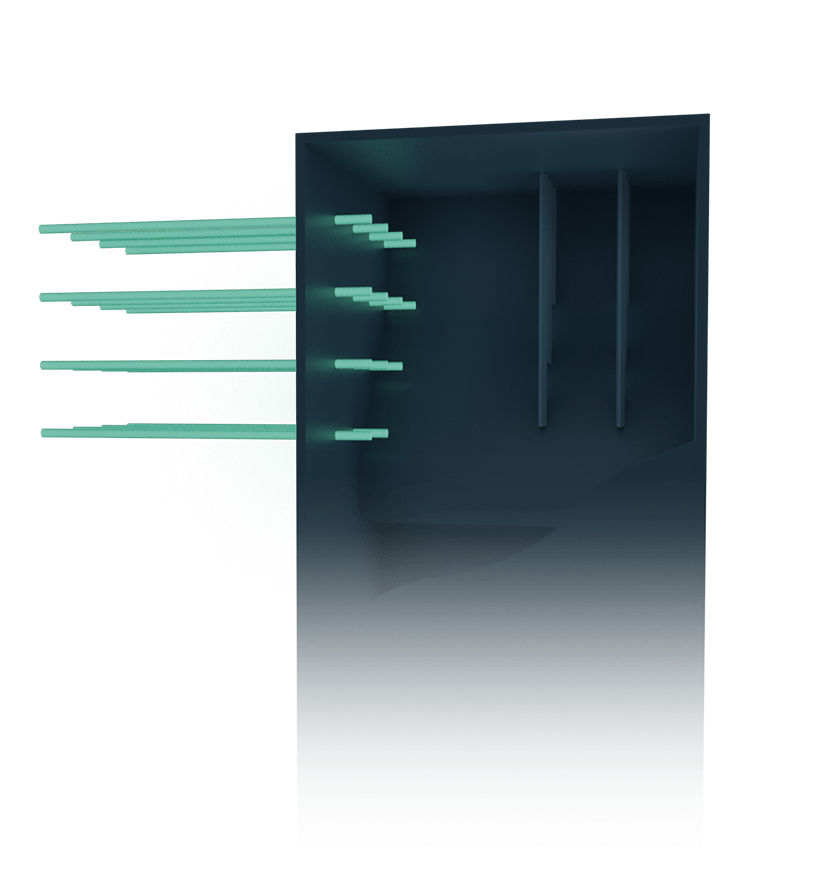

More than 90% of the cleaning by a sootblower takes place during the sootblower’s initial stroke.

When the sootblower is retracted, 50% of the steam is used unnecessarily while the soft ash is sintered into concrete-like deposits.

With HISS® (High Impact Sootblowing System), several sootblowers can be operated in parallel with or without return steam, i.e. more sootblowing, less steam, more easily removed ash.

See how it works

About HISS

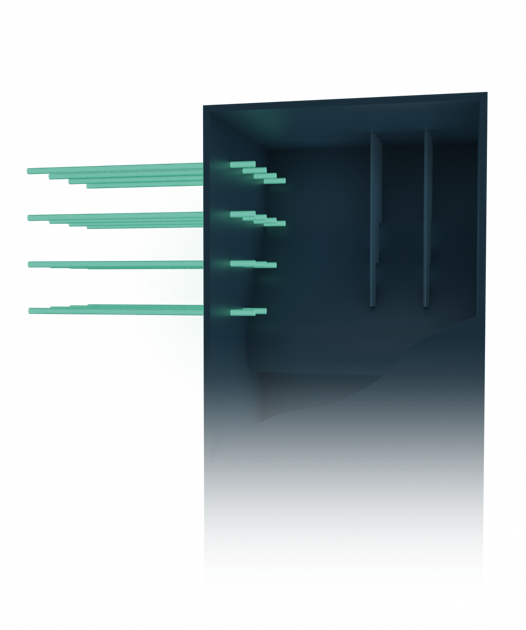

HISS transforms your steam sootblowing system

The patented HISS® technology transforms your steam sootblowing system into an effective tool that handles clogging and increases the efficiency of your power and recovery boilers.

- Halve your steam consumption

- Increase your production of electricity

- Double your sootblowing power

- Use cheaper fuel

Works on all soot blower valves/brands. Rosink, Clyde Bergemann, Diamond Power etc.

Key facts

100% increase

In sootblowing capacity, without installing new sootblowers, or consuming more steam.

45 % reduction

In steam consumption, per sootblower.

Beyond technical specification

One year process follow-up increases boiler availability and efficiency

Do you want to optimize your sootblowers?

Talk to one of our experts to see if our renowned High Impact Sootblowing System would be fitting for you.

Downloads

Optimized steam sootblowing

Heat Management among the top 5 percent in EcoVadis’s sustainability assessment – awarded Gold Medal.

EcoVadis is a trusted global provider of business [...]

Heat Management Landed 3 new Purchase Orders During the Summer of 2024!

Introduction During the summer vacation, we have kept ourselves [...]

Heat Management featured in “Dagens Industri”

Below is a translated version of the article in [...]

Two more HISS orders from one of the largest pulp and paper conglomerates in the world.

One of the largest pulp and paper manufacturers in [...]