General info

Payback within 6-24 months after implementation

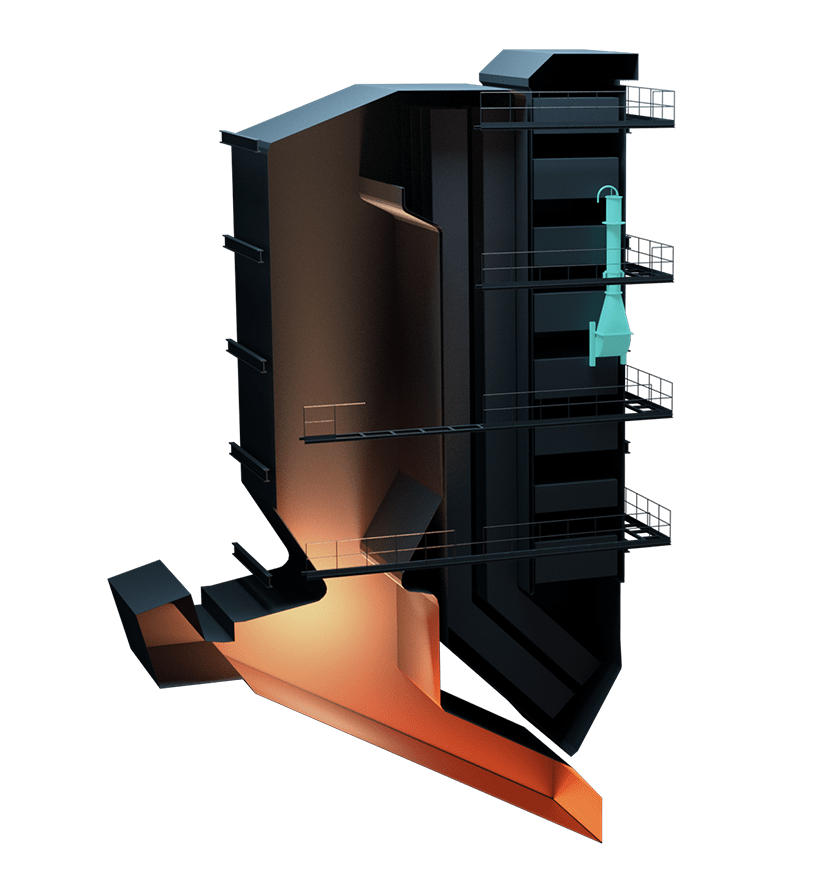

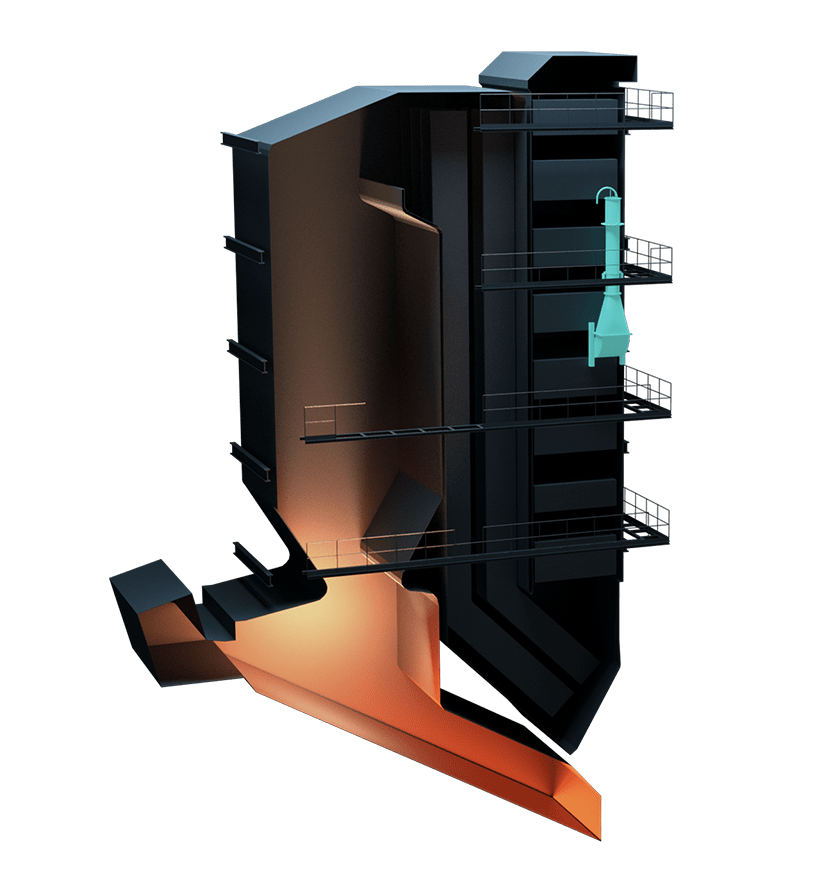

Our Infrafone cleaners (low-frequency acoustic cleaning) improves the profitability of boilers. This has been achieved thru more efficient soot cleaning in e.g. economizers, air-preheaters and catalysts (SCR’s), with a general payback time of about 6 to 24 months. Traditional soot cleaning technologies such as steam sootblowing, shot cleaning, sonic cleaning (high frequency), and manual cleaning are generally heavily reduced or eliminated in these applications.

Our range of products is the result of our unique knowledge and our customer focus. We calculate the optimal size and design of the acoustic cleaner for each customer’s particular need and the spatial possibilities of each installation.

See how it works

Key facts

Higher efficiency

From automatic, frequent preventive cleaning of heating surfaces and catalysts.

50-75 %

Reduced steam sootblowing, increasing asset lifetime by less wear and higher efficiency

Stable operation

From more frequent and preventive cleaning

Does Infrasound sound interesting?

Talk to one of our experts to see if Infrasound Cleaning would be a fitting solution for you.

Downloads

Articles related to Infrasound cleaning

Siemens Energy collaboration

Siemens Energy AB initiates collaboration with Heat Management regarding energy efficiency improvements in black liquor boilers on pulp mills.

Swedish Södra Cell teams up with Heat Management

From a tight cooperation between Värö mill and Heat Management, a specific solution was developed that will materialize in a seamless integration of Heat Managements patented solution HISS.

2 more orders on HISS

The new orders are for a black liquor boiler [...]

Heat Management bring in business in Spain

Spain is an interesting market in many aspects for [...]