General info

Payback within 6-24 months after implementation

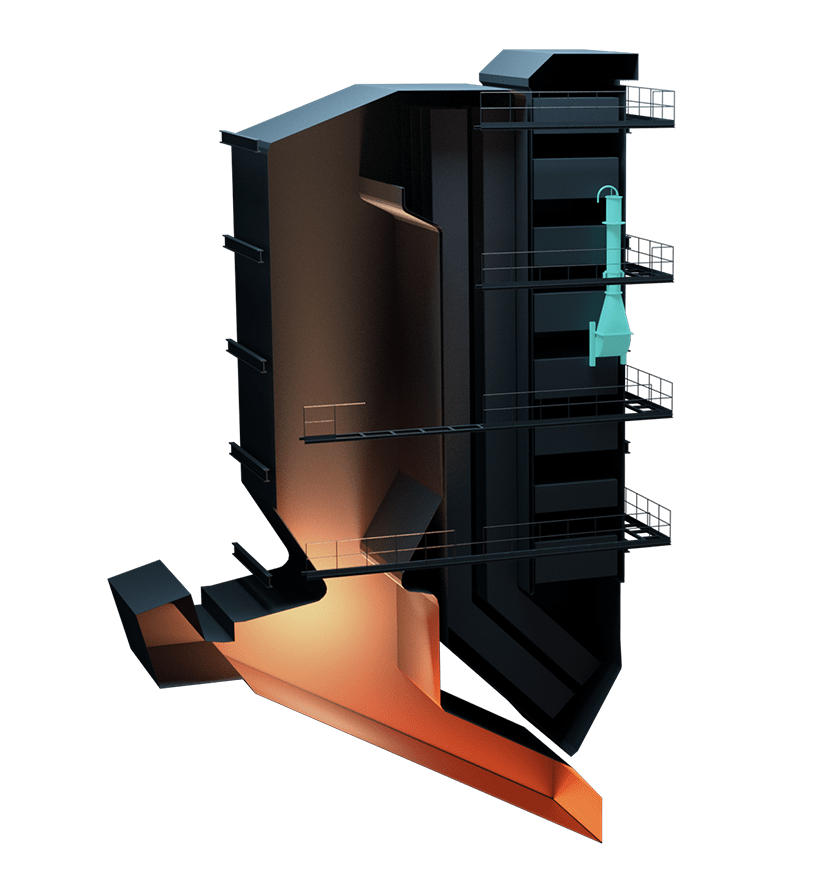

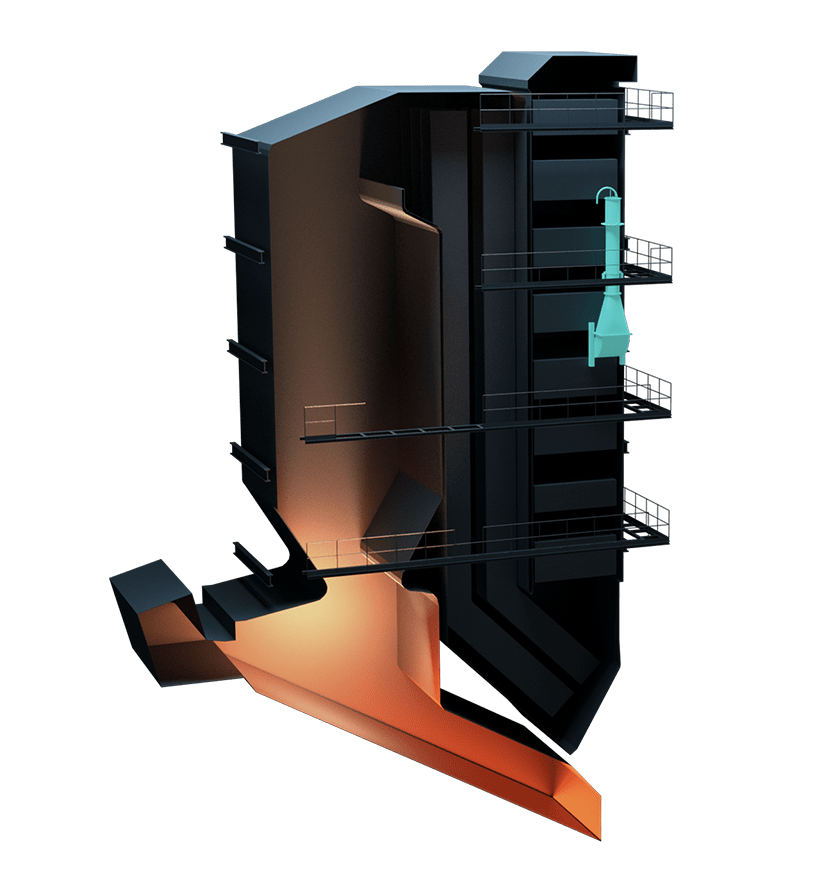

Our Infrafone cleaners (low-frequency acoustic cleaning) improves the profitability of boilers. This has been achieved thru more efficient soot cleaning in e.g. economizers, air-preheaters and catalysts (SCR’s), with a general payback time of about 6 to 24 months. Traditional soot cleaning technologies such as steam sootblowing, shot cleaning, sonic cleaning (high frequency), and manual cleaning are generally heavily reduced or eliminated in these applications.

Our range of products is the result of our unique knowledge and our customer focus. We calculate the optimal size and design of the acoustic cleaner for each customer’s particular need and the spatial possibilities of each installation.

See how it works

Key facts

Higher efficiency

From automatic, frequent preventive cleaning of heating surfaces and catalysts.

50-75 %

Reduced steam sootblowing, increasing asset lifetime by less wear and higher efficiency

Stable operation

From more frequent and preventive cleaning

Does Infrasound sound interesting?

Talk to one of our experts to see if Infrasound Cleaning would be a fitting solution for you.

Downloads

Articles related to Infrasound cleaning

Heat Management joins ABB Partner Program

Heat Management joins ABB Partner Program Heat Management [...]

Sustainable operations

Veracel Celulose recovery boiler CR01 (photo courtesy of Mr [...]

Improved sustainability strategy for the energy sector

THE IPCC 2021 presents clear evidence that our planet is in a catastrophic state of urgency to stop global warming. Human influence has affected the atmosphere, ocean, and land. Why do we, in the energy sector, need to take responsibility?

How to master the fouling challenges with biofuel- and waste-to-energy boilers

The driving force behind this is to contribute to the sustainability goals. Since biofuels burn faster and cleaner than fossil fuels, they will release greenhouse gases at a lower and slower rate. Secondly, the use of biofuels will allow the economy to reap its benefits.