General info

Payback within 6-24 months after implementation

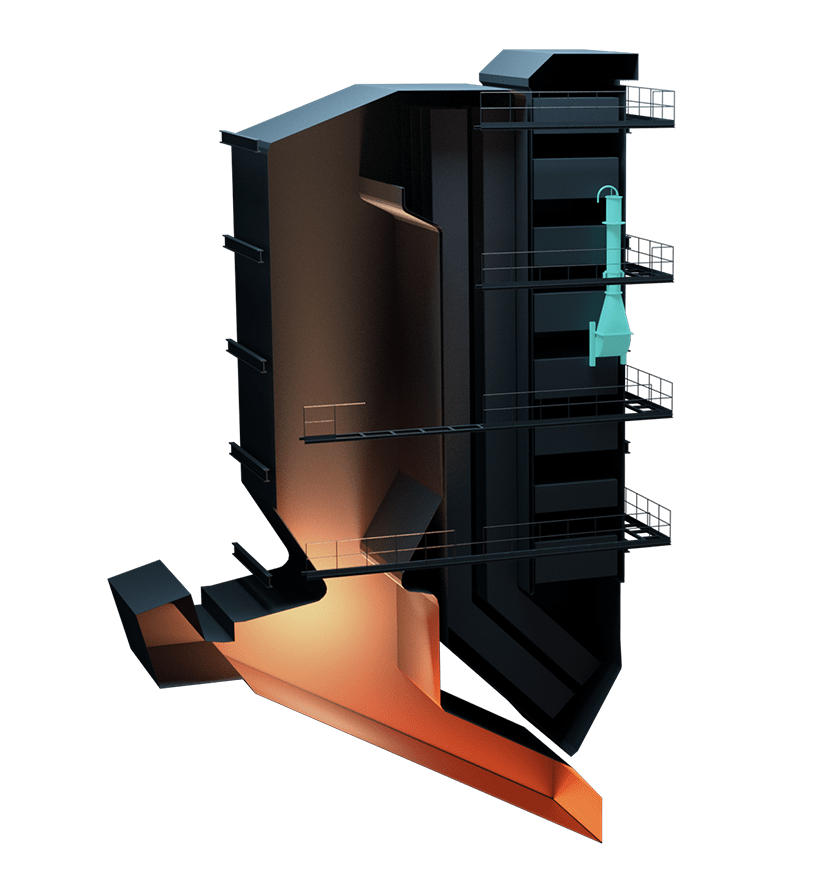

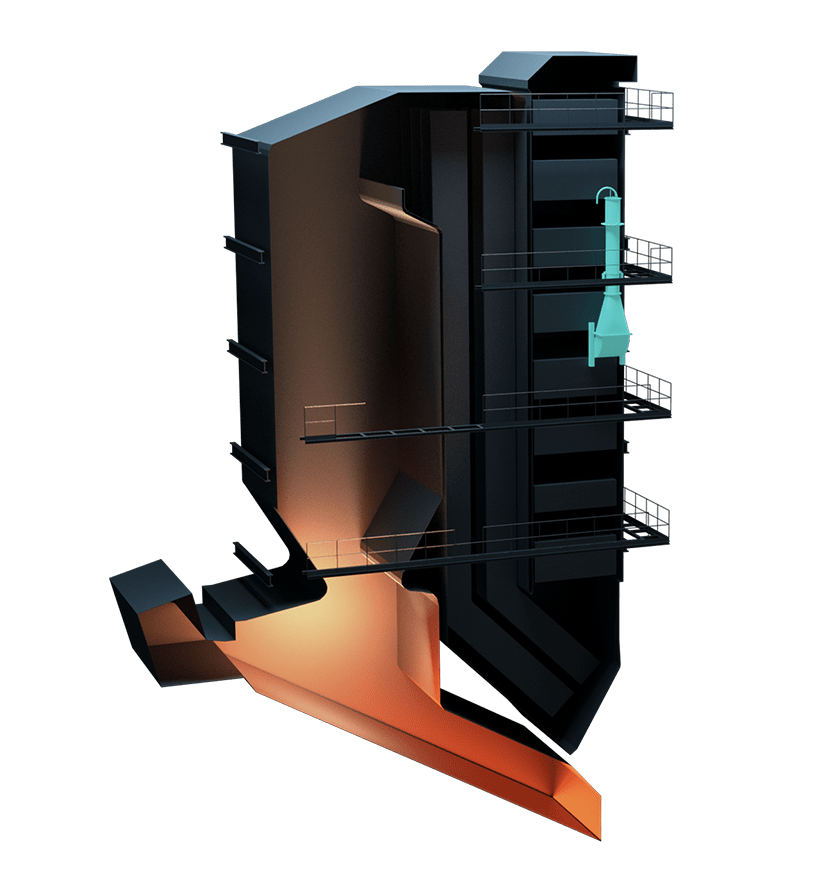

Our Infrafone cleaners (low-frequency acoustic cleaning) improves the profitability of boilers. This has been achieved thru more efficient soot cleaning in e.g. economizers, air-preheaters and catalysts (SCR’s), with a general payback time of about 6 to 24 months. Traditional soot cleaning technologies such as steam sootblowing, shot cleaning, sonic cleaning (high frequency), and manual cleaning are generally heavily reduced or eliminated in these applications.

Our range of products is the result of our unique knowledge and our customer focus. We calculate the optimal size and design of the acoustic cleaner for each customer’s particular need and the spatial possibilities of each installation.

See how it works

Key facts

Higher efficiency

From automatic, frequent preventive cleaning of heating surfaces and catalysts.

50-75 %

Reduced steam sootblowing, increasing asset lifetime by less wear and higher efficiency

Stable operation

From more frequent and preventive cleaning

Does Infrasound sound interesting?

Talk to one of our experts to see if Infrasound Cleaning would be a fitting solution for you.

Downloads

Articles related to Infrasound cleaning

Record Number of Orders in the year of 2023 for Infrasound Cleaning Systems

Heat Management’s Infrasound cleaners has been exceptionally popular historically [...]

Sustainable Steam: Jönköping Energi’s HISS Project and its Impressive Results

In 2023, the Swedish power plant Jönköping Energi initiated [...]

Johan Holmér’s Amazing Recap from BLRBAC 2023

In this article Johan Holmér gives a recap from his presentation at BLRBAC. He explains how the old ways of wasting the pulp and paper mill's resources prevents the process of streamlining production and lowering emissions.

Revolutionizing Fuel Analysis for Pulp and Paper mills: Heat Management’s Newest Tech Acquisition

The Acospector takes a whole new approach on process [...]