General info

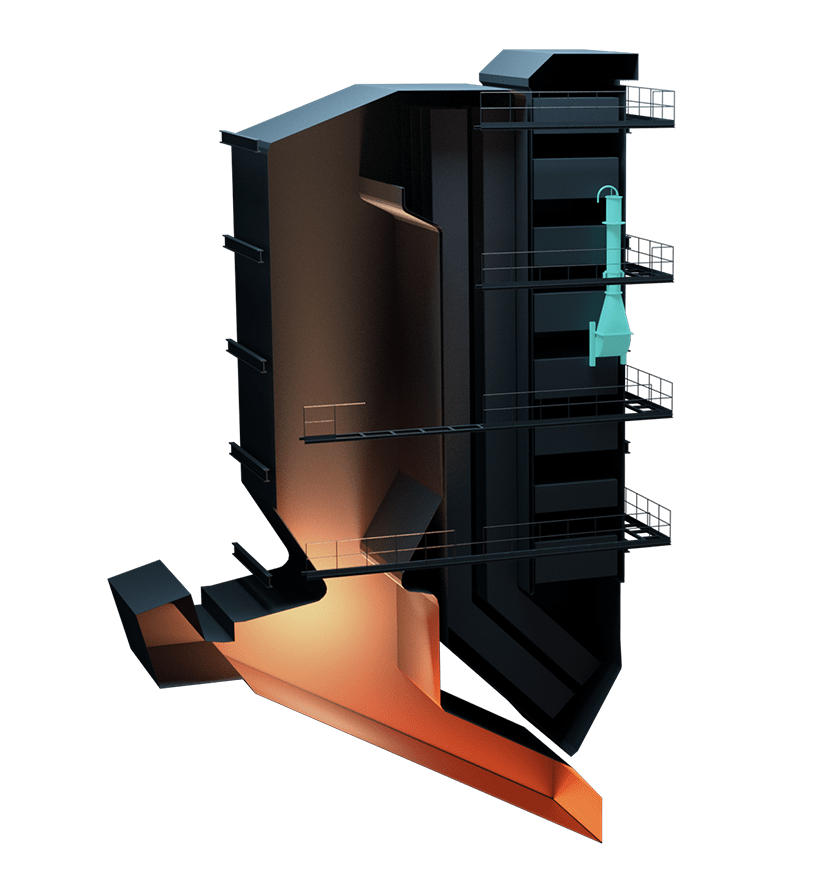

About Biomass boilers

Biofuels offer challenges in order to reach high efficiency and availability. Biofuel normally tends to create gas-side fouling in all parts of the boiler.

About cleaning

Benefits of our soot cleaning systems for Biomass boilers

Reduced steam consumption for steam sootblowing. Saved sootblower steam is used for increasing heat or electricity production.

Lower fuel consumption. Cleaner tubes mean increased heat transfer and efficiency.

Lower and more stable differential pressure. Infrasound cleaning reaches areas that are not accessible to conventional soot cleaning systems. This means higher availability of the boiler and lower load on ID/FD fans.

Fewer and shorter outages for manual cleaning. With improved cleaning effect you can obtain higher availability and fewer man-hours spent.

Increased lifetime of heat exchangers. By reducing or eliminating steam sootblowing or shot cleaning, the lifetime of heat exchangers is prolonged. Infrasound cleaning is a non-abrasive cleaning method that does not wear on heat exchange surfaces or catalyst elements and does not contribute to corrosion or erosion. Using our optimized steam sootblowing also reduces wear since steam is supplied only half the time.

Articles related to Biomass boiler

High Impact Sootblowing System (HISS) as a solution for lower environmental impact for pulp mills and power boilers.

During the last few years, our optimized steam sootblowing technology HISS™ has been gaining momentum in central and northern Europe. The acceptance of the technology following the proven results and several other benefits.

Carbon capture project with cement producer Norcem will significantly lower carbon footprint using infrasound soot-cleaning

The Brevik Carbon Capture and Storage project reduce CO2 emissions by 400,000 tonnes a year, paving the way for a net-zero carbon footprint for the cement lifecycle. Heat Management joins forces with Aker Carbon Capture by supplying powerful infrasound cleaning technology to keep the waste heat recovery boilers clean.

We wish you a sunny, relaxing and healthy summer break

Summer is here, and it is time to take a moment to stop and reflect. What a year 2021 has been so far. The dream of getting back to normal is finally becoming a reality, and businesses are regaining their confidence.

Siemens Energy signs cooperation agreement with Heat Management to reduce the global CO₂ footprint in the pulp- and paper industry

Siemens Energy and Heat Management have entered a strategic partnership to jointly contribute to a global reduction of the CO₂ footprint in the pulp and paper industry.