General info

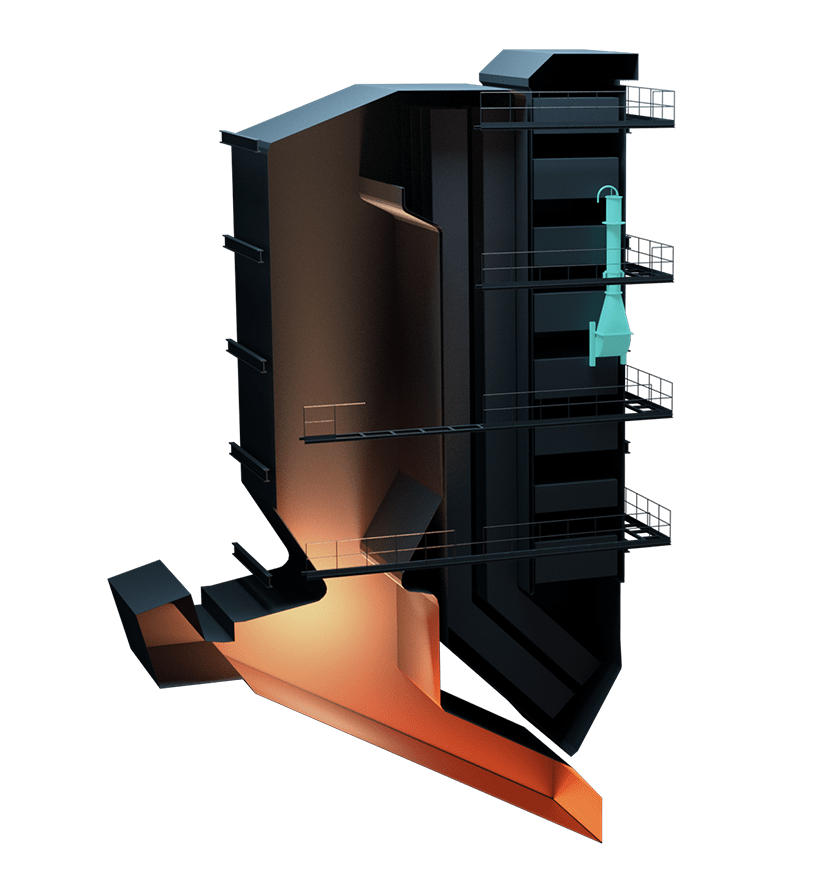

About Biomass boilers

Biofuels offer challenges in order to reach high efficiency and availability. Biofuel normally tends to create gas-side fouling in all parts of the boiler.

About cleaning

Benefits of our soot cleaning systems for Biomass boilers

Reduced steam consumption for steam sootblowing. Saved sootblower steam is used for increasing heat or electricity production.

Lower fuel consumption. Cleaner tubes mean increased heat transfer and efficiency.

Lower and more stable differential pressure. Infrasound cleaning reaches areas that are not accessible to conventional soot cleaning systems. This means higher availability of the boiler and lower load on ID/FD fans.

Fewer and shorter outages for manual cleaning. With improved cleaning effect you can obtain higher availability and fewer man-hours spent.

Increased lifetime of heat exchangers. By reducing or eliminating steam sootblowing or shot cleaning, the lifetime of heat exchangers is prolonged. Infrasound cleaning is a non-abrasive cleaning method that does not wear on heat exchange surfaces or catalyst elements and does not contribute to corrosion or erosion. Using our optimized steam sootblowing also reduces wear since steam is supplied only half the time.

Articles related to Biomass boiler

Heat Management joins ABB Partner Program

Heat Management joins ABB Partner Program Heat Management [...]

Sustainable operations

Veracel Celulose recovery boiler CR01 (photo courtesy of Mr [...]

Improved sustainability strategy for the energy sector

THE IPCC 2021 presents clear evidence that our planet is in a catastrophic state of urgency to stop global warming. Human influence has affected the atmosphere, ocean, and land. Why do we, in the energy sector, need to take responsibility?

How to master the fouling challenges with biofuel- and waste-to-energy boilers

The driving force behind this is to contribute to the sustainability goals. Since biofuels burn faster and cleaner than fossil fuels, they will release greenhouse gases at a lower and slower rate. Secondly, the use of biofuels will allow the economy to reap its benefits.