General info

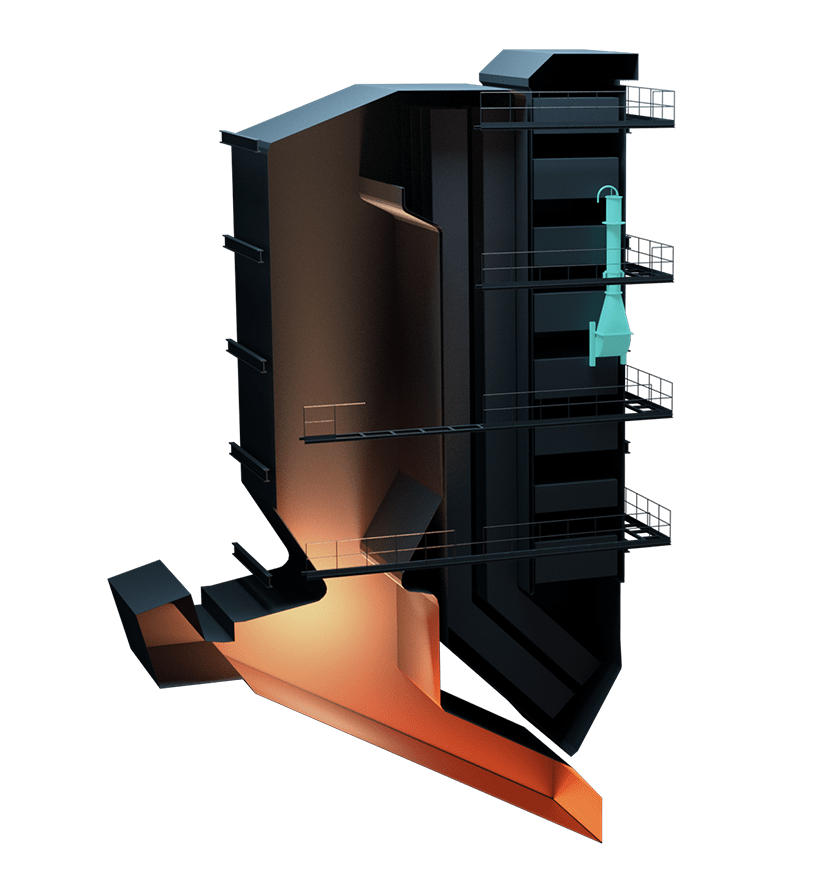

About Biomass boilers

Biofuels offer challenges in order to reach high efficiency and availability. Biofuel normally tends to create gas-side fouling in all parts of the boiler.

About cleaning

Benefits of our soot cleaning systems for Biomass boilers

Reduced steam consumption for steam sootblowing. Saved sootblower steam is used for increasing heat or electricity production.

Lower fuel consumption. Cleaner tubes mean increased heat transfer and efficiency.

Lower and more stable differential pressure. Infrasound cleaning reaches areas that are not accessible to conventional soot cleaning systems. This means higher availability of the boiler and lower load on ID/FD fans.

Fewer and shorter outages for manual cleaning. With improved cleaning effect you can obtain higher availability and fewer man-hours spent.

Increased lifetime of heat exchangers. By reducing or eliminating steam sootblowing or shot cleaning, the lifetime of heat exchangers is prolonged. Infrasound cleaning is a non-abrasive cleaning method that does not wear on heat exchange surfaces or catalyst elements and does not contribute to corrosion or erosion. Using our optimized steam sootblowing also reduces wear since steam is supplied only half the time.

Articles related to Biomass boiler

Heat Management among the top 5 percent in EcoVadis’s sustainability assessment – awarded Gold Medal.

EcoVadis is a trusted global provider of business [...]

Heat Management Landed 3 new Purchase Orders During the Summer of 2024!

Introduction During the summer vacation, we have kept ourselves [...]

Heat Management featured in “Dagens Industri”

Below is a translated version of the article in [...]

Two more HISS orders from one of the largest pulp and paper conglomerates in the world.

One of the largest pulp and paper manufacturers in [...]